The manufacture of the custom-made tension spring

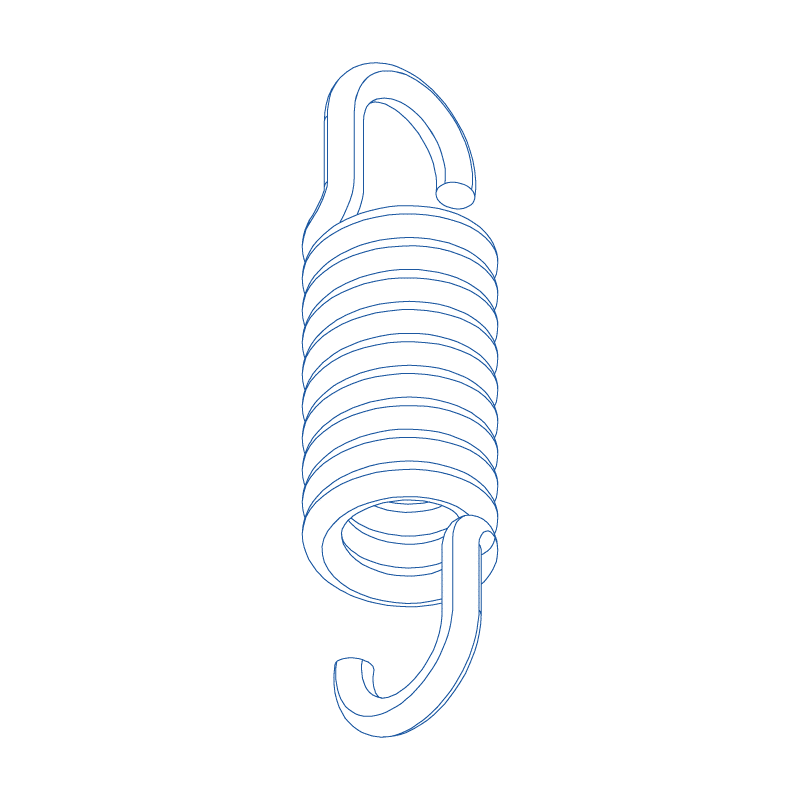

A tension spring is, as its name suggests, intended to undergo deformation by tensile force. Thanks to the shape memory of its specific material, it can restore this energy to return to its original position. The tension spring often has a loop at its ends. They allow it to be extended during a traction and then to return to its position at the time of release. Helical in shape, the tension spring is according to use when it grows and in rest function when it shrinks.

Intended to be extended, the tension spring is most of the time manufactured with the coils attached. This gives him the opportunity to stretch without difficulty. In terms of manufacturing, the tension spring can be directly pulled out to the machine when the ends are made of German loops. For English loops, the spring is machine-wound but the loops are handmade. The German and English rings are the most important ends commonly used for tension springs.

Use of the tension spring

The tension spring is used in two ways, either in constant tension or in repeated tension. Then, the force used to extend the tension spring is either applied to both ends at the same time or to only one. In this second case, either the second end is just hung or it is directly fixed.

Several uses for the tension spring, especially for :

Create a movement

Control a movement

Guide a movement

To undergo tension between two masses

Avoid friction between two elements

Hang an element on its loop

Move two masses away from each other

Ensure the fall of a mass

It can be seen that there can be a multitude of uses for the tension spring, however they are not all stated. Indeed, the use of the spring depends on the environment in which it works and also on its function. As a manufacturer of custom springs it is possible to adapt to all constraints for its use.

Function of the tension spring

To understand how the tension spring works, you have to imagine an invisible axis around which the material is wound. The spring is manufactured in such a way that each side of the turn is equidistant from the axis. The tension spring can exert a perfectly straight stroke towards the outside while remaining in a straight axis. It can also be slightly twisted (maximum 15 % tolerable).

Bore

The tension spring operates in a bore if the size of the bore is larger than the outer diameter of the spring.

Height

The minimum height of the tension spring is reached when the turns are all joined. At the moment of rest when no force is applied.

The maximum height is reached when the spring is in operation. It is maximum when the height of the yarn is equal to the height of the spring. However, the tension must remain normal so as not to damage the spring.

Define the form of the tension spring

Different types of ends :

English ring : represents a loop of at least one turn. The loop is in the opposite direction of the turns. The end is then in contact with the wire.

German ring : does not represent an entire circle and leaves an empty space at the end of the loop. The end is then not in contact with the wire.

The half loop: identical to the German loop but equal to half a turn.

The double loop : double ring starting in both directions of the end.

The tangent ring : corresponds to a loop located on one side of the turn.

The clean cut : the end is similar to that of a compression spring but on a tension spring. This makes it more difficult to exert pressure on them.

The hook : this type of end has a hook shape.

The movable hook : starts from the spring axis which is conical or biconical. It forms a circular hook.

The stem : perfectly straight and has no hook.

Screwed end: plate integrated at the end of the spring, which can then be screwed to a surface.