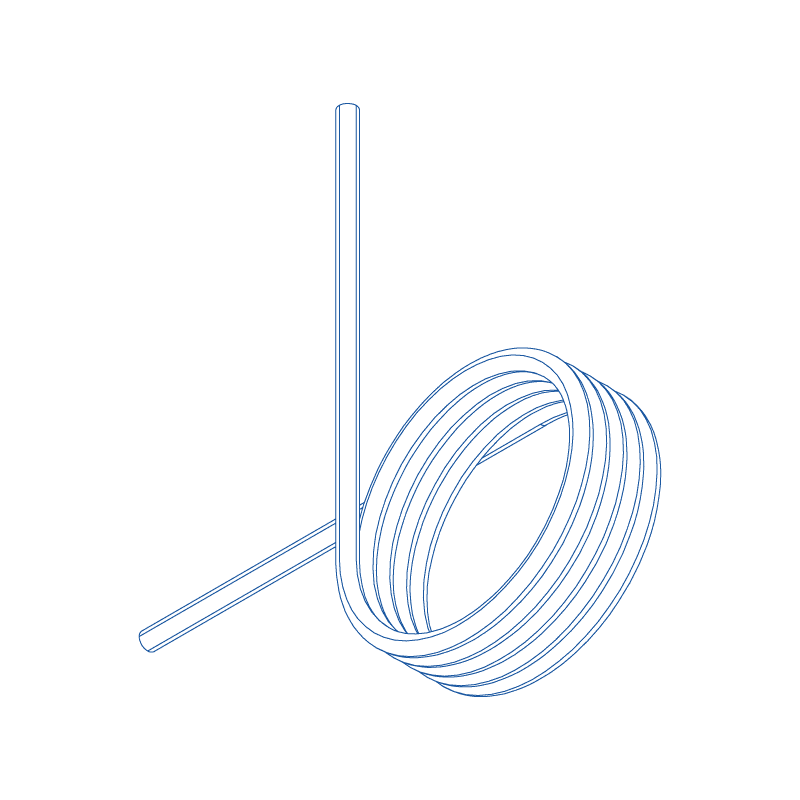

The manufacture of the custom-made torsion spring

A torsion spring is intended to undergo deformation by mechanical energy of torsion, rotation, bending or bending.Thanks to the shape memory and elastic properties of its specific material, it can restore this energy so as to return to its original dimension. The torsion spring has the specificity of exerting a rotative force in action and then a reverse rotation in order to return to its resting position.

Apart from the specificity of its ends, the torsion spring is identical to the helical springs. It is depending on usage during bending, bending, rotation or torsion. It is based on rest when there is no contact with the extremities.

The torsion spring rotates according to an angle.It accumulates and releases energy through the angle when the sides deform relative to the body. Unlike other springs, the torsion spring is more complex to manufacture, especially because of its ends. This includes the angle, length and type of branches. Several other parameters are then taken into account for the computations of force and stiffness.

Use of the torsion spring

The torsion spring is used to work in a rotating manner by exerting a force on its branches. Like all other types of springs, the torsion spring can be found under different uses, but here are some situations where we see it most often :

Create a folding movement

Create a bending movement

Control a movement

Guide a movement

To undergo a movement between two masses

Prevents friction between two elements

Pull or push on its ends

Move away or bring two masses closer together

Carry or be carried by masses on the torsion spring

Block or be blocked by a mass

Function of the torsion spring

The force exerted must be in the direction of winding. Its deformation conditions depend on the angle of rotation and the ends. If the force exerted is contrary to the direction of winding of the spring, there is a risk of loss of torque. In general, the torsion spring works around a longitudinal axis that passes through the centre of its body.

The bending stresses are mainly in the spring body. The space in which the torsion spring evolves must be taken into account because the torsion spring, depending on its state changes volume.When used, the length of the body increases but the diameter decreases. At rest, it has a smaller body and a larger diameter. The lower the winding angle, the more difficult the spring will be to perform bending work.

Define the expected shape of the torsion spring

To make a spring there are criteria common to all spring families such as wire diameter, outer diameter, body length, number of turns, stiffness and material.

For the parameters specific to the torsion spring there is the angle of the branches :

0°

90°

180°

270°

And the types of ends :

Extrémités tangentes

Extrémité radiales

These two types of ends are the most commonly used, they are the basic ones. However, there are many others because the wire can then be formed at the customer’s request.