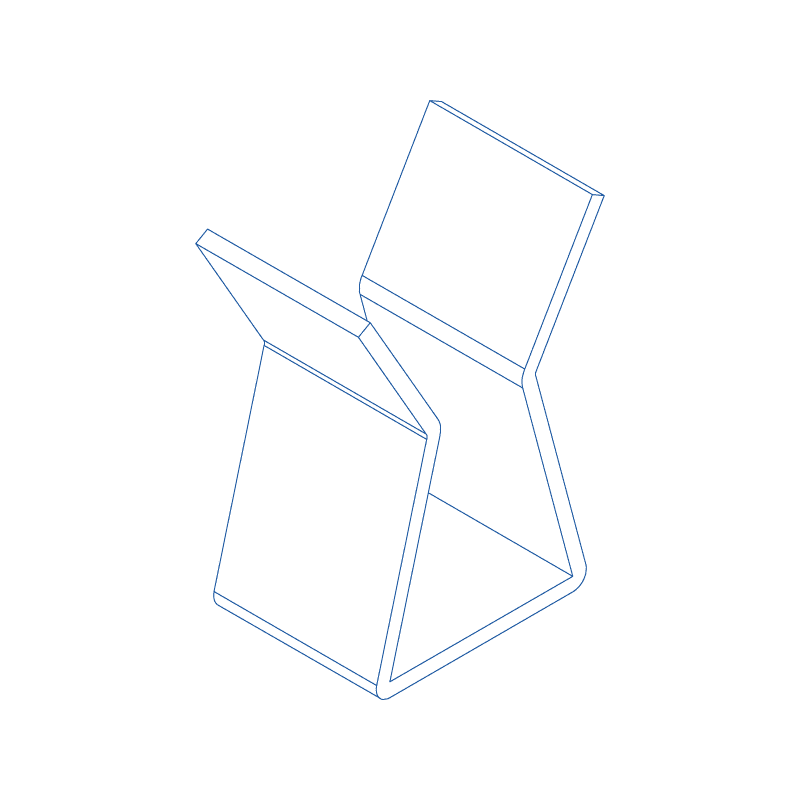

The manufacture of custom-made flat spring

A flat spring is intended to undergo many types of deformation by mechanical energy, thanks to the shape memory of its specific material. It restores this energy so as to return to its original dimension. The flat spring has a number of possibilities of infinite shapes and therefore a capacity to make many movements: bending, compression, traction, lever, rotation, bending, balance…

The flat spring is depending on usage when a mass is applied to it. It is dependent on rest when it returns to its original form when it is no longer in contact with a load. The flat spring can be a substitute for wire springs however its manufacture is diametrically opposed due to the non-use of wire. Indeed, in the absence of other families of springs, the flat spring is not made of wire but from strip which is a thin plate of material similar to a blade. This is why the flat spring is also called blade spring.

Use of the flat spring

The flat spring is mainly used as a replacement for a coil spring when its operating space is constrained by size, because the flat spring takes up less space. It is exclusively designed as a custom-made spring.

Its different characteristics allow it to be able to :

Create a bending, projection, traction movement....

To be an alternative to a compression, traction, torsion spring

Control a movement

To undergo a movement between two masses

Prevents friction between two elements

Pull or push on its ends

Move two masses away from or closer to each other

The use of the flat spring does not only stop at the spring function. Due to its strip material it can be used as a clip or as a support for example.

The operating of the flat spring

The flat springs can sometimes turn around an axis and the strip will wind around this axis at the manufacture of the spring. This will give it a spiral shape. However, it can work very well without winding around this axis.

Some flat springs work under constant load. In this case, a load is applied to all points of the spring to create the movement. Due to the material blade several pressure points are required.

Space is less constrained than for helical springs and can be used as a substitute for them.

Bore

The flat spring can be integrated more easily into a bore because it is generally used as a replacement for the coil spring and is less voluminous.

Define the expected shape of the flat spring

The materials used mainly for this type of spring are :

Stainless steel 301 (flat stainless steel spring)

Steel XC75 (flat steel spring)

To manufacture a flat spring, there are different manufacturing methods :

Stamping : Cutting by deformation of metals under press.

Punching : Cutting of metals by perforation.

Laser : Made with large amounts of energy produced by a laser

NC bending : method of bending from a machine (CNC bending machine)